Araldit Laminating Resin Ottobock

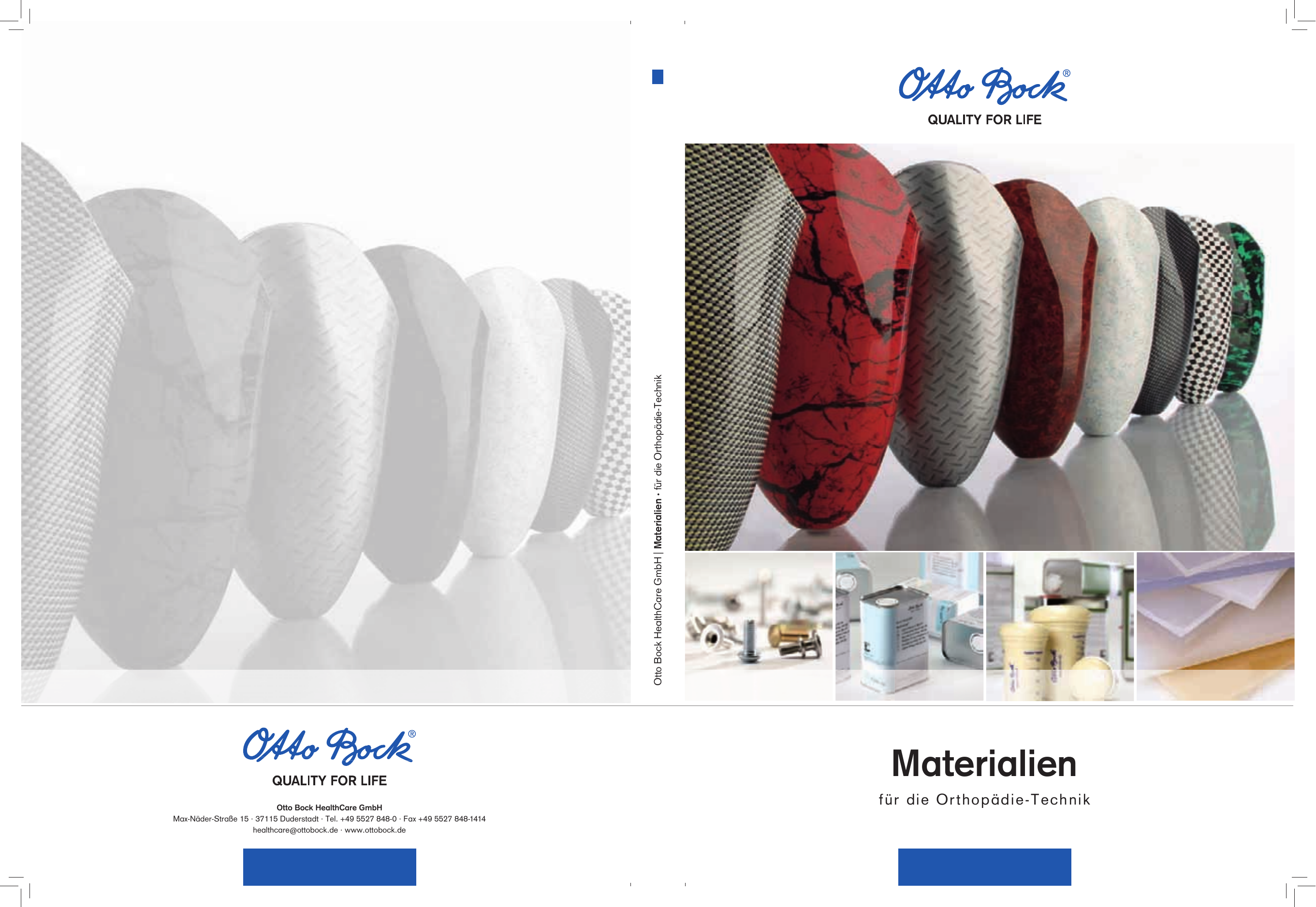

The most versatile of laminating resins orthocryl resins are specifically formulated for the fabrication of carbon fiber glass or textile lamination lay ups.

Araldit laminating resin ottobock. Thanks to the lower viscosity the reinforce. This achieves a high degree of stiffness at a low laminate wall thickness which falls between that of an acrylic resin and that of an epoxy resin. Orthocryl lamination resin 80 20 pro is a lamination resin for the fabrication of components with a low proportion of resin. The most versatile of laminating resins orthocryl resins are specifically formulated for the fabrication of carbon fiber glass or textile lamination lay ups.

800 463 3659 e mail. For casting carbon on carbon no filter layers are required. Cast the resin all at once and not gradually which is done with conventional resins. Nevertheless orthovinyl can be processed as quickly and easily as an acrylic resin.

617h119 orthocryl lamination resin 80 20 pro ottobock 3 orthocryl lamination resin 80 20 pro is a lami nation resin for the fabrication of components with a low proportion of resin. The methyl methacrylate base provides excellent strength for each specific application and use. Recommendations for lamination resins acrylic resins epoxy resin orthocryl sealing resin orthocryl lamination resin 80 20 orthocryl lamination resin 80 20 pro c orthocryl c orthocryl sanitized orthocryl soft orthocryl extra soft araldit lamination resin article number 617h21 617h19 617h119 617h55 617h255 617h17 617h51 617h4. 800 962 2549 e mail.

Laminating resin systems or laminating pastes usually follow the coupling layer during mould construction and represent the actual mould structure with their properties and the usually introduced reinforcing fibres. The most versatile of laminating resins orthocryl resins are specifically formulated for the fabrication of carbon fiber glass or textile lamination lay ups. It has a lower viscosity than orthocryl lamination resin 80 20 617h19 but the same mechanical characteris tics. Lamination resin for carbon fiber.

For sheet casting use only 616f4 pva film or 99b81 pva bags. Smaller components can be laminated more quickly thanks to the shorter curing time. The methyl methacrylate base provides excellent strength for each specific application and use. Our laminating resins are suitable for all common application processes in mould making as well as in component production.

It has a lower viscosity than orthocryl lamination resin 80 20 617h19 but the same mechanical characteristics. The standard ottobock 617p37 0 150 hardener can be used.