Aqueous Coating Vs Matte Lamination

With an appearance that s between gloss and matte satin offers medium shine and.

Aqueous coating vs matte lamination. Matte lamination has a velvety texture that makes it pleasant to handle. It is available in gloss satin and matte finishes. A great example of the glossiness of uv coating are baseball trading cards. High volume production of many packaging applications prohibits the use of thermal lamination because of the expense of the film itself and the slower off line application used to apply the film compared to uv or water based coatings.

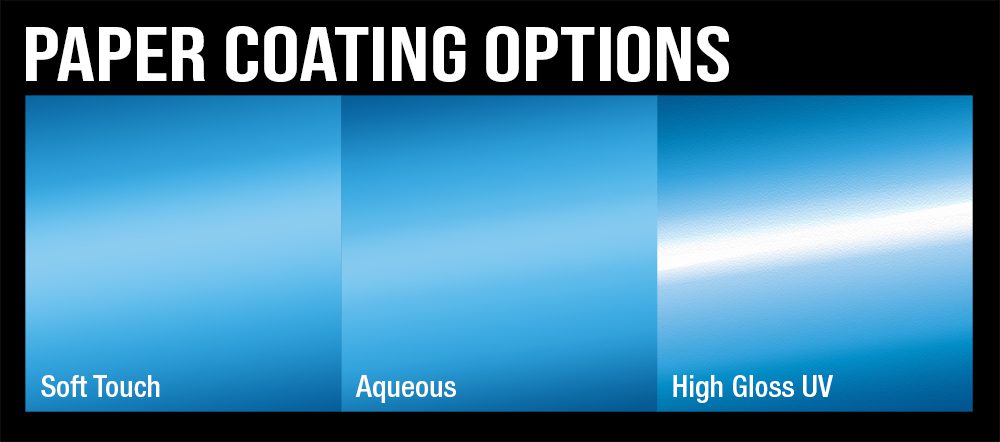

Coatings allow various finishes such as high gloss gloss semi gloss matte and with a roller even more options such as soft touch and other textures. In fact the choice between matte vs. Trading cards in general have a uv coating on the photo side and no coating on the stat side. It also provides a softer more natural look that makes it easier to read the printed piece.

Different types of aq aqueous coating. The initial cost to implement the uv coaters into a shop may be higher than a lamination setup especially if a ventilation system has to be put into place. When plastic coating is added to any item it becomes tear proof and waterproof since the laminating film encapsulates the item completely by bonding it to both sides. Polypropylene lamination is the most popular and least expensive laminate available today.

Consider matte coating for minimal shine and depth but a high degree of color. Matte and gloss aqueous coatings are very cost effective and do not add any extra time to the production of your printed project. If you re looking for a less showy and more muted gloss finish aq coating is an ideal solution for a high gloss uv coating or film laminates are better options.